Flanged Fittings are Better Than Ferrules for Alpkem, Perstorp or OI Analytical Autoanalyzers

Autoanalyzers vary by manufacturer on what type of fittings they use to secure tubing into the reaction manifold as well as the other various fittings on the system. Some just use sleeves where the tubing simply slides over a nipple or some kind of connector. This doesn’t create a very good seal and shouldn’t be used for anything but reagents since sample can be caught in this loose fitting causing tailing or poorly shaped peaks. Others use a nut and ferrule where the nut is placed on the tubing and then a ferrule is slid onto tubing. When the nut is tightened into the receptacle the ferrule compresses to form a seal. The ferrule material is designed to be softer material so that it compresses to form a seal when tightened.

The problem with ferrules is that they inevitably get too compressed. After several tightenings the opening at the end of the tubing gets very small, usually much smaller than the ID of the tubing itself. This point of restriction sooner or later will cause flow issues such as surging and clogs which can affect peak shape and reproducibility.

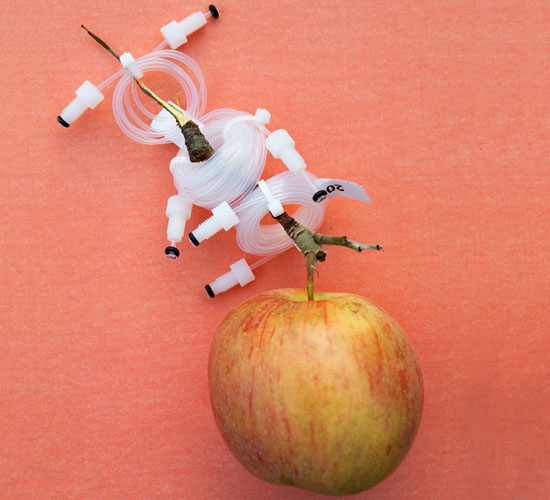

Flanged fittings are an alternative to nut and ferrules made from Teflon tubing. Flanged fittings use a similar nut as with a ferrule but the connection is made with an o-ring and a melted or compressed ring of the tubing at its end. When the nut is tightened down the ring is pressed against the end by an o-ring that compresses. With a flanged fitting, over tightening is not an issue since once the o-ring is compressed the seal is perfect without occluding any of the tubing, leaving the entire opening of the tubing intact for proper flow of solutions. When it is removed the o-ring returns to its original shape and the o-ring material is impervious to any chemicals that may come into contact and at that point it can be screwed back into the opening as many times as required without damaging or limiting the life of the fittings.

A ferrule realistically can only be tightened down once or twice before it loses all ability to compress and form a seal. After a few times then when it is screwed back in it must be tightened more and more to form a complete seal which invariably decreases the size of the opening at the tube end and restricts proper flow of solutions through the connection. At this point in the life of a ferrule, since it can no longer form a good seal, operators will sometimes turn to a pair of pliers to tighten even further since leaking is still occurring which will only lead to possibly catastrophic clogs and ironically still not stop the leaking since the ferrule is compressed beyond its ability to seal. Sometimes this over tightening response can lead to considerable damage to the manifold such as cracking at the nut port. I have even seen operators put Teflon tape on the nut to stop the leaking. Unfortunately, ferrules are not cheap, need to be replaced regularly and even then, new ferrules can cause problems, especially if the nut has to be removed even semi-regularly.

A flanged fitting, on the other hand, can potentially last forever. When a flanged fitting tightens down it does not interfere with the inner dimensions of the tubing path, it seals by a gasket and not a constriction to keep leaking from occurring. Most likely the tubing itself will need to be replaced long before the fittings ever wear out. Because the o-ring and the nut itself can be reused over and over; all that is required to fix a worn tubing assembly is new tubing and the device that forms the flanged fittings. I regularly convert chemistry manifolds without a significant increase in cost to the customer, over to Teflon tubing and flanged fittings and see significant improvements in flow, sensitivity, peak shape and reproducibility. If you have any questions about this please feel free to contact us and we can talk about these issues in more depth as they relate to your specific laboratory settings.

Leave A Comment