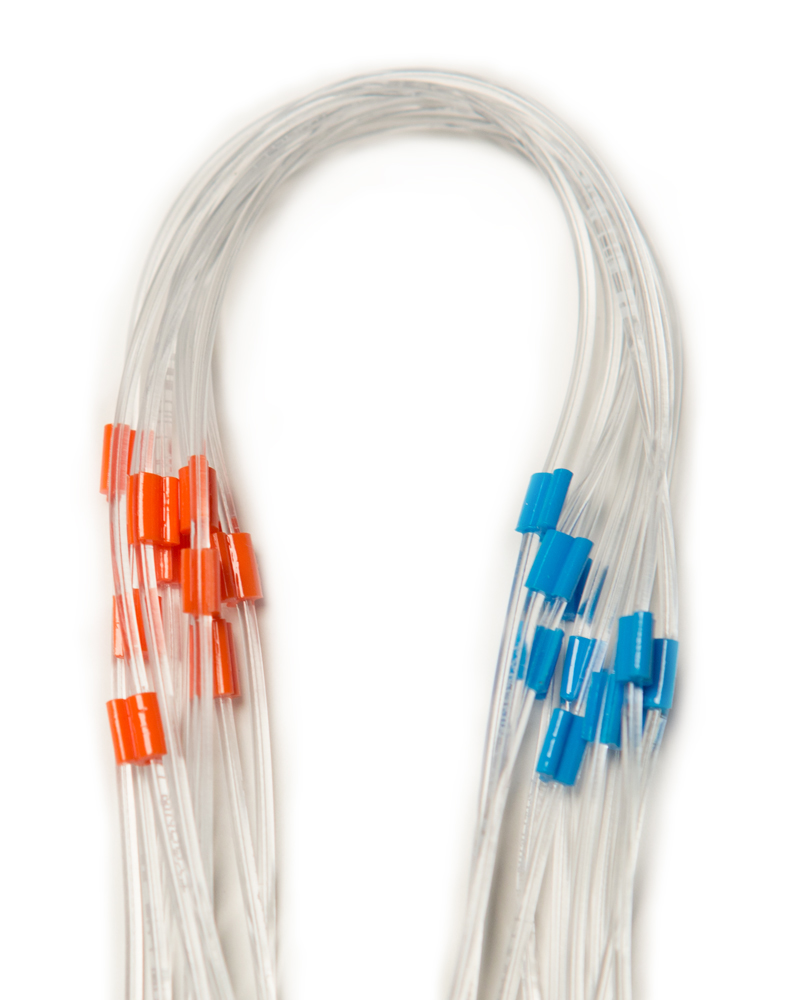

Various Pump Tubing Materials, Compatibility and Applications

Peristaltic pumps rely on compressing and releasing a length of flexible tubing to mimic natural peristalsis seen in many biological systems, using positive displacement to move fluids in a steady and smooth pulsing manner. Instrument Systems will remain contamination-free using peristaltic pump tubes, since the only part of the pump touched by the solution is the interior of the tubing.

Click here for the Laboratory Tubing Overview

This is especially the case for OI Analytical systems which use luer lock fittings on the closed lids and caps of all reagents containers to protect the solutions themselves, operators and from the environment where the equipment is installed. The pump tubes Peristaltic pump tubes are made of a variety of materials that is ultimately determined by the solution being pumped.

Click here for the Pump Tubing Overview

One of primary reasons to choose a peristaltic pump is its ability to handle difficult fluid without damaging pump components since the solutions are entirely contained in the pump tubes themselves. Tubing can be selected to handle difficult fluids allowing the proper selection of cost, durability and brands of peristaltic pump tubes. Please check this compatibility chart for specific information on various types of tubes and chemicals.

Click here for the Compatibility Chart

For instance a solution with more than 5% alcohol would require a different type of material known as silicone than a solution with 1 M Sulfuric Acid and no alcohol. The most common material is called Tygon, a transparent PVC type material that has great resistance to most Acid and Base solutions less than 3-5 M. Tygon or Vinyl (PVC) has the lowest per-foot cost of any peristaltic pump tubing and is the most common on the OI Analytical Autoanalyzer systems. It has only fair compatibility for many aqueous solvents and does not have any tolerance for most organic solvents.

Vinyl tubing cannot be autoclaved and should not be exposed to temperatures above 80°C. Silicone is the most commonly used peristaltic pump tubing. It has the longest service life and good chemical compatibility for aqueous and many organic solvents and is often used on the Sulfate chemistry which contains alcohol. It can usually be left running on experiments during weekends without much danger of rupture, but a fresh tubing change should be performed before any running peristaltic pump is left unattended for many days.

Silicone tubing can also be autoclaved a single time with a wet cycle without a significant reduction in its life. The other more vigorous tubing used is the Flouroelastomer which is both the most chemically inert peristaltic pump tubing and the shortest lived. It can withstand even halogenated solvents for a short time often used with MBAS which pumps chloroform.

All of these types of flexible peristaltic pump tubing require periodic replacement and the peristaltic pumps themselves require maintenance needs which we will discuss in future segments of this series.

For more information and helpful videos, make sure to follow us on Facebook and Youtube!